DEFINITION OF PROTECTION

INDEX

1. OCCUPATIONAL RISK ASSESSMENT

2. MACHINERY DIRECTIVE

3. SAFETY SWITCHES

4. RELIEF MEASURES: RELIEF MEASURES PROJECT

5. ALUMINUM PROFILES: CHOICE FOR ACCIDENT PREVENTION PROTECTIONS

6. PROTECTION SYSTEMS: FIXING ON THE EDGE OF THE MACHINE OR ON THE GROUND

7. DOOR OPENING

8. GAS SPRING: OPERATION

9. PANELS: PLUGGING FOR PROTECTION SYSTEMS

10. ACCIDENT PREVENTION PROTECTION: DOORSTOPS AND FUNCTIONS

11. INDUSTRIAL SOUNDPROOFING: WHAT IT CONSISTS OF

OCCUPATIONAL RISK ASSESSMENT

Regulated by EN ISO 12100, Occupational Risk Assessment is aimed at reducing or eliminating risks. Action is taken at three levels:

- At the source, acting on the structure.

- Through the Protection and Control Systems.

- Through the training of practitioners.

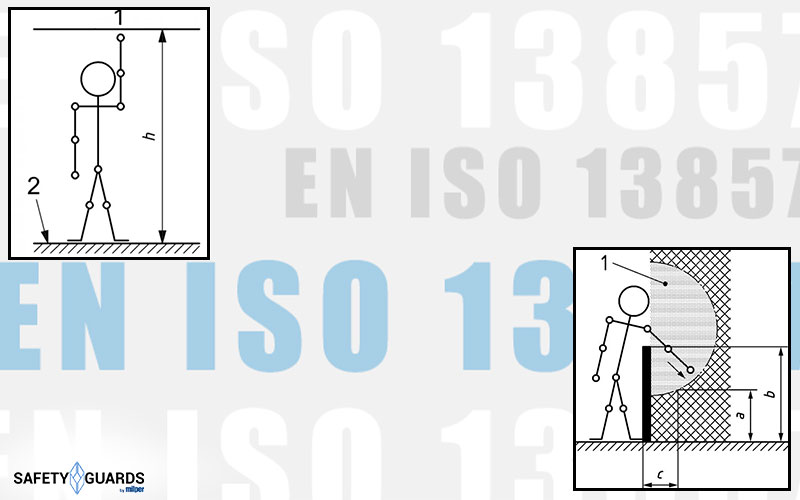

Technical Standard EN ISO 13857, regulates the distance between the source of danger and Protection Systems. Classified as B1, the Technical Standard also considers non-industrial encumbrances, in fact it promotes the protection of children from three years of age.

The evaluation of the Safety Distance should not be altered; it is not permissible to vary the reference plane or use tools that can bring the upper limbs closer to the hazard source. The Safety Distance, should in fact be considered from the most protruding part of the body.

The extent of this distance, varies with a proportional relationship to the level of risk. According to the Technical Standard, the limiting measurement of a vertical slot, cannot exceed 180mm; 240mm is the square or circular measurement in order to prevent access. Safety Guards cannot measure less than 100mm.

Technical Standard EN ISO 13857 Safety Distance

MACHINERY DIRECTIVE

CE Marking indicates the machine’s compliance with the Machinery Directive 42/2006/EC. In the event of a Workplace Accident, the Employer, is liable for failure to verify compliance with European Technical Standards. In fact, the employee must be instructed about the use of the machine and Safety Devices, they must be operational.

The RSPP is the figurehead about compliance with the Technical Standard in this regard. The same Employer may hold the position of manager, and is prosecutable according to Art. 33 of Legislative Decree: 81/08. Essential elements accompanying the machine are, the instruction manual for operation and maintenance and proper training of personnel.

In the case of Quasi Machine, the Machinery Directive provides for a simple “Declaration of Incorporation,” since CE Marking covers the entire modular apparatus capable of doing the work. This is important in case of major changes to the machinery, such as to change the operation, since in this case it is necessary to remark according to the CE Technical Standard. Intervention steps, should take into account the guidance on safety and residual risks.

SAFETY SWITCHES

EN ISO 14119 is the Technical Standard on Interlocking Devices, in addition to the choice of apparatus type, the installation of Safety Switches is also regulated. Interlocking Devices are categorized into four types:

- TYPE 1: Operated by an actuator without coding.

- TYPE 2: Operated by a coded actuator.

- TYPE 3: Not in contact with the uncoded actuator.

- TYPE 4: Not in contact with the coded actuator.

The requirements in this regard are clear and are based on the principle of preventing Safety Protection from being circumvented. For Type 1 Safety Switches, those with rotary or linear cams are required:

- An assembly at a distance from the operator.

- Application of an obstruction to prevent operator access.

- Installation in concealed location.

- Attachment of actuator and device.

- Insert a control circuit test.

For Type 2 and 4 Safety Devices with level-coded actuators:

- LOW: The previous directions apply, except for the fixing of actuator and device.

- HIGH: Serves only the non-removable fastener.

RELIEF MEASURES: RELIEF MEASURES PROJECT

Industrial Protection Sizing, requires a Sizing phase. The measurement of the machine can be done directly or through its 3D drawing. When using the 3D file, it is a good idea to make sure it is in the *STEP or STP* extension to ensure a compatible format on most software.

The 3D model must be oriented correctly, matching the origin points of the drawing and the real environment. Having viewed the machine directly is the best way to avoid inaccuracies.

ALUMINUM PROFILES: CHOICE FOR ACCIDENT PREVENTION PROTECTIONS

The choice of Aluminum Profile is critical to designing the Structure and any Doors. Recommended combinations are:

- 32×32 (Main Aluminum Profile Structure) and 18×32 (Doors).

- 45×45 (Main Aluminum Profile Structure) and 32×32 (Doors).

The Aluminum Profile and Accessories, should be chosen according to the size, weight, Doors and type of anchorage of the Industrial Protection. The forces and loads that could act on the Industrial Protection (vibrations for example) should be considered.

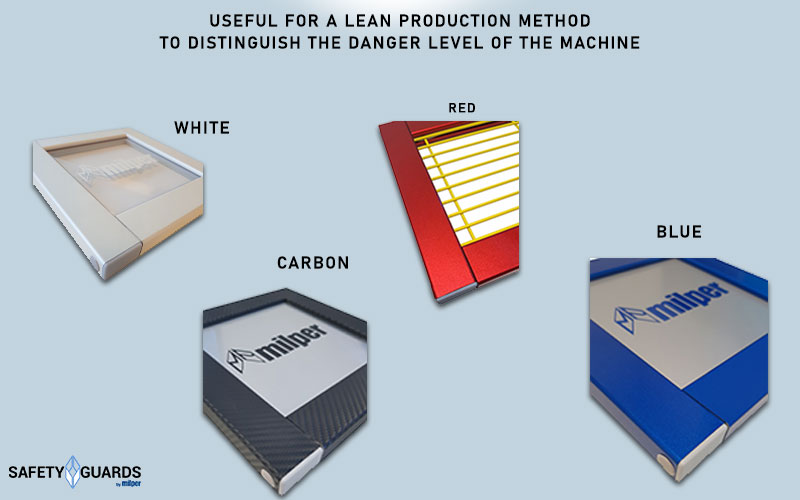

The application of Colored Films is an element of adding textures, colors and company logos. This provides a shiny metallic finish that can add a performance appearance to Safety Protection. Indeed, Colored Films are distinguished by their resistance in multiple types of environments.

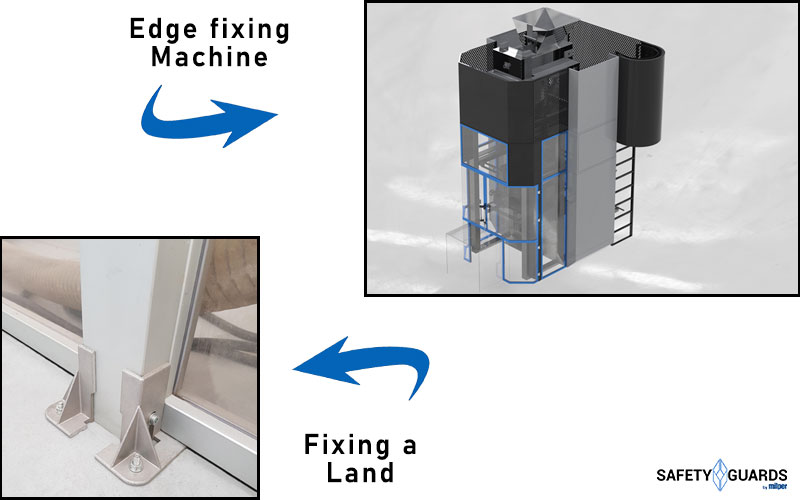

PROTECTION SYSTEMS: FIXING ON THE EDGE OF THE MACHINE OR ON THE GROUND

For machine attachment, it is good to evaluate the anchor points of the Industrial Protection. At the level of the machine, these should be fixed where the machine is most stable and strong. It should be assessed that there is no impact between the internal fastener and the machine components in action.

The number of fasteners should be commensurate with the weight and size of the Safety Protection. Easy installation should also be encouraged. Work on a newly made machine can be based on pre-drilling, so that clean work is done. For anchor points, it is preferable to use the slots in the Aluminum Profiles, here threaded nuts can be inserted, and additional anchor points can be added.

The use of a closed 32×32 Aluminum Profile is more suitable for settings subject to strict hygiene measures. Accessories and Blankets, are insertable inside the removable tabs. For ground fixing, it is essential to check the stability of the support base. The thickness and condition of the pavement should be checked: a test hole is useful for choosing the type of anchors.

You can then, proceed to the placement of Safety Protection according to the design. When drilling with an impact drill, the presence of sensitive structures, located under the floor, is good. If this is impossible, it is necessary to consider the solution of the stringers connected to the machine itself. Anchor Bases, can be made of die-cast Aluminum, steel or painted iron, to be chosen according to the size of the Industrial Protection.

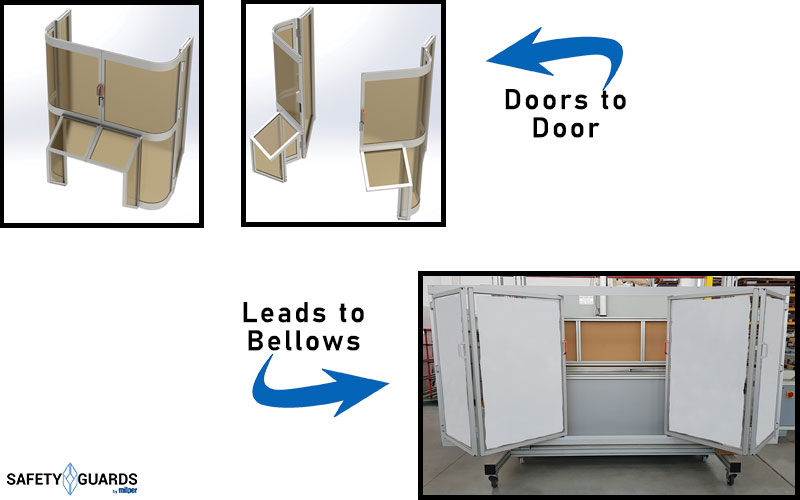

DOOR OPENING

The choice of the type of door is related to the evaluation of the overall dimensions around the apparatus to be protected q the frequency of opening of the Fall Protection. The Swing Door is the most classic. This involves at least two Hinges and at least one Handle mounted on the opposite side from the Hinges.

Alternatively, other types of Openings can be evaluated. The folding opening, can be adapted to large compartments. This allows full access to the machine. It is important to put to the Sliding Accessories: they are to be chosen to operate by rolling friction, as ball bearings are preferred. The Vertical Sliding Door, can be a viable alternative if it is possible to employ a counterweight system to be housed within the Aluminum Profiles.

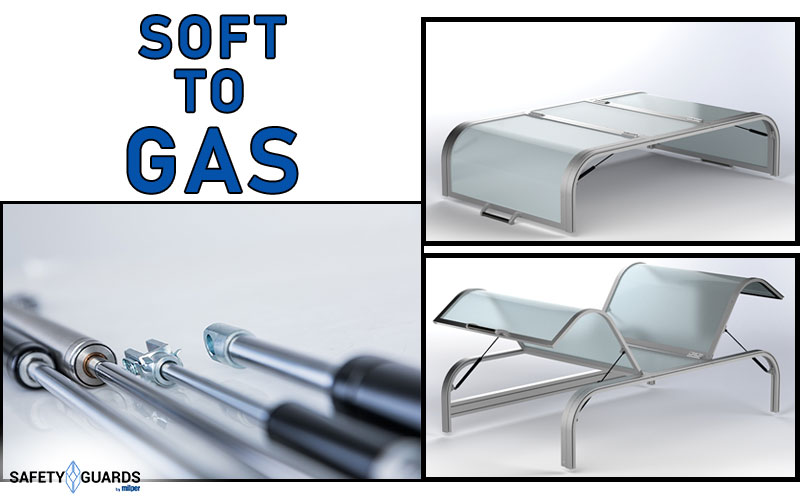

GAS SPRING: OPERATION

The structure is constructed from a steel cylinder with nitrogen content under pressure and a rod running inside, which passes through a sealing ring. Compared with the mechanical system, the Gas Spring has a curvature Of almost flat strength, even for long runs. A Gas Spring has a life cycle of 100,000 opening and closing cycles, this value is reduced if welding is done near the device, due to thedamaging effect by acetone.

Opening the Doors Upward, may employ a Gas Spring system to support the weight. Attention should be paid to running and pushing force. The first aspect, it must ensure full movement in both closing and opening. You need to evaluate the minimum height of the Door Opening, to facilitate reaching the Handle.

The second aspect, must consider the weight of the Door and the location of the Gas Spring attachment points. The thrust force, should be calculated considering the vertical application of forces.

Gas Springs can be free-stroke, or lockable stroke. The attachments include two types:

- Hole-hole: ideal for limited rotation perfect alignment. It is best not to use threaded pins in order to reduce friction.

- Articulated: used in major rotations and less than perfect alignment.

The use of Gas Springs should be avoided in the following cases:

- Excessive vibration.

- Instead of shock absorbers.

- Unfavorable environment (corrosive, temperature above 80°C).

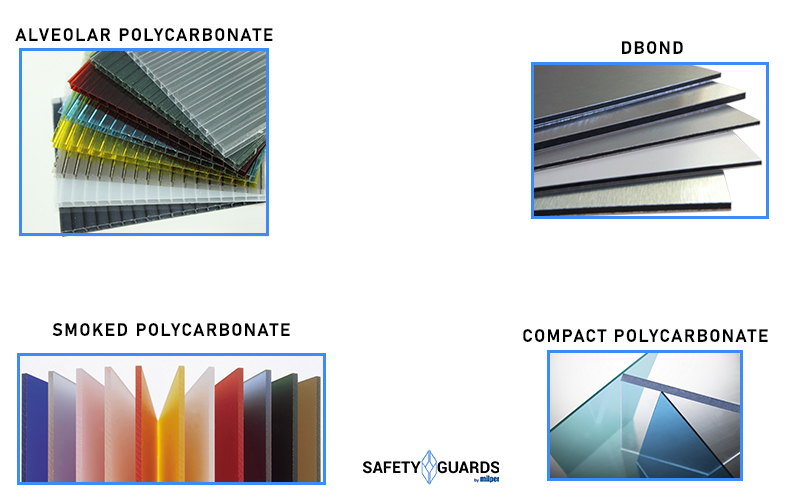

PANELS: BUFFERS FOR PROTECTION SYSTEMS

Solutions available for Closing Panels, include Polycarbonate, Dbond and Metal Mesh.

The Compact polycarbonate is weatherproof. This has excellent mechanical properties with respect to elongation, loads and shocks. The material lets light through, weighs half as much and is 250 times stronger than glass. Good are the properties of thermal insulation and acoustic.

However, the merit of the high degree of Self-extinguishing is accompanied by a high ability to attract dust. The Polycarbonate Honeycomb Is lighter than the compact one, but is less transparent. It is the material of choice for the roofs ofPrevention Guards, as it shows less dirt.

The material is an excellent thermal insulator and a good shield from UV rays. Polycarbonate Fumé, has similar characteristics to the types already described, and has color gradations ranging from gray to brown. Dbond Curtain Walling, consists of two prepainted Aluminum foils, heat-bonded together on a central layer of extruded Polyethylene, in a “sandwich” structure.

In addition to being self-extinguishing, the material resists chemicals, weathering and has soundproofing properties. The Metal Mesh, on the other hand, is a grid of steel wires. This resists bending, cutting, and is more rigid than the other proposed solutions.

ACCIDENT PREVENTION PROTECTION: DOORSTOPS AND FUNCTIONS

I Door stops should be chosen at the design stage, these can be classified into three types. Le Magnets can be chosen according to the pull strength. This is the easiest type to install. They are to be avoided on machines with iron chip removal, so as not to impair functionality.

Le Mechanical Locks should be preferred in the presence of vibration. La Cremonese Handle, takes advantage of the movement of one or two rods mounted on the door, to be inserted on the fixed frame. If applied directly on the Polycarbonate, this type of Handle demonstrates an especially stable closure.

INDUSTRIAL SOUNDPROOFING: WHAT IT CONSISTS OF

A cause of damage to the auditory system, noise emission in the production environment can also affect the operator’s level of emotional stress. Assessing this exposure is the way to ensure safe prevention. Risk is expressed by the LEQ (equivalent continuous sound level), a parameter indicating the sound energy to which the operator is exposed in a span of time.

Reducing noise pollution is possible by going through the steps of measuring sound absorption of the environment, and measurement of noise emissions from sources. Interventions should include the use of vibration damping materials, the design of the plant layout, and acoustic correction Of the environment.

Le Soundproof Cabins are the devices that shield noise emissions from individual machinery. The technologies employed, include sound barriers, the Soundproof Cabins And sound-insulating and sound-absorbing walls. The choice of device varies depending on the acoustic energy, in other types of energy (this is the case of the porous sound absorbers).

Example of Soundproof Cabins with

Soundproofing Material