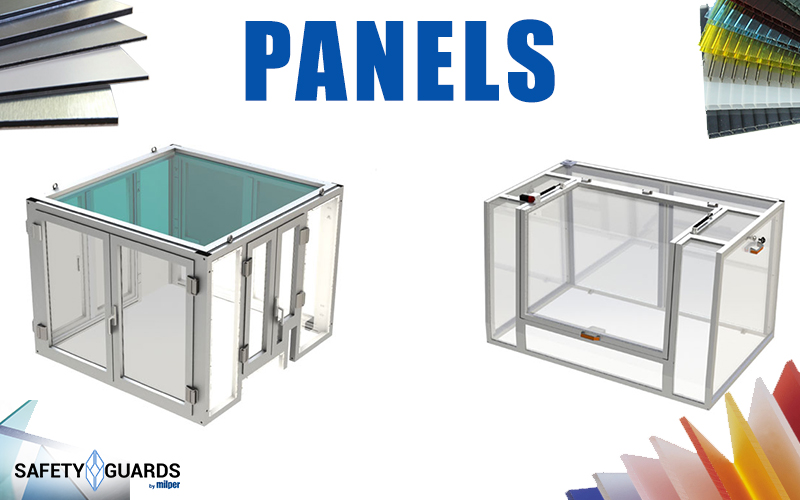

PROTECTIVE PANELS

INDEX

1. CLADDING: ASPECTS TO CONSIDER

2. PANELS: COMPACT POLYCARBONATE – ALVEOLAR POLYCARBONATE AND SMOKED POLYCARBONATE

3. DBOND PANELING AND METAL NET

4. SUMMARY ON PANELS

CLADDING: ASPECTS TO CONSIDER

If the load-bearing function of a part is recognized to the Aluminum Profile frame, the cladding, used for the perimeter partitions and closures, awaits the task of filling the void that is created between the frames themselves.

The importance of the Panels (or infills) is dictated by the fact of determining the ability of an Accident Prevention Protection, to limit as much as possible, for example, the heat exchange between the internal and external environment. The market is now able to offer different types of infill panels, starting from panels in compact polycarbonate, flanked by panels in honeycomb Polycarbonate and Smoked Polycarbonate, but also infill in Dbond and wire mesh. able to offer different types of infills, starting from the compact polycarbonate panels, flanked by the panels in alveolar polycarbonate and smoked polycarbonate, but also the infill in Dbond and the metal mesh. different types of infills, starting from the compact polycarbonate panels, which are flanked by the alveolar polycarbonate and fumé polycarbonate panels, but also the dbond infill and the metal mesh.

How to choose the industrial protection panel solution that best meets your specific needs? Simply by evaluating a series of factors: from the impacts to which the Accident Prevention Protection is subject during the execution of the works, to the degree of transparency up to the degree of acoustic insulation.

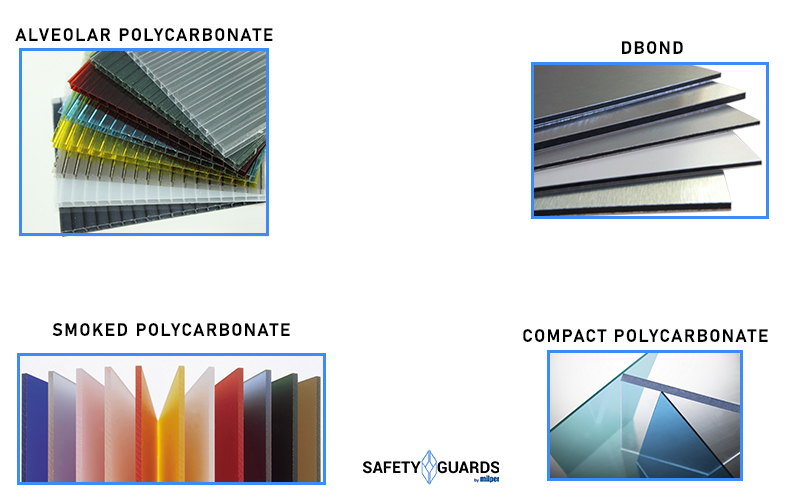

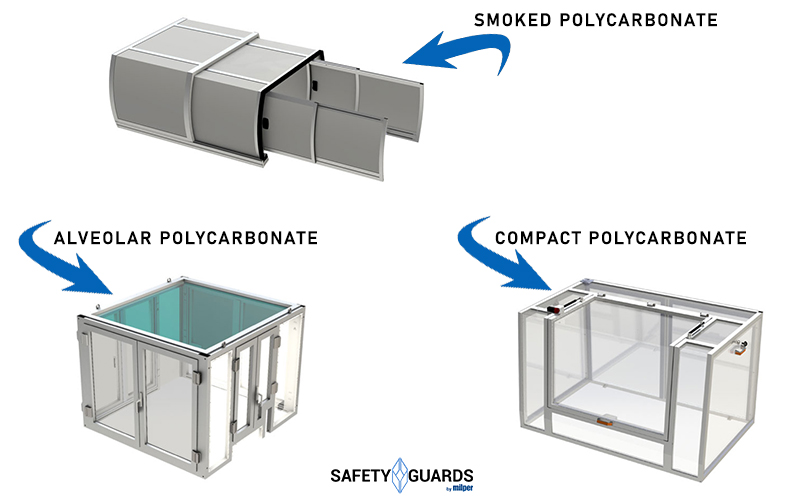

PANELS: COMPACT POLYCARBONATE – ALVEOLAR POLYCARBONATE AND SMOKED POLYCARBONATE

The strength of the Compact Polycarbonate curtain wall is its resistance to heat (up to 120 ° C) and water temperature (max 70 ° C). Other appreciable characteristics are the ability to offer a good passage of light and a resistance greater than that of glass.

The degree of self-extinguishing also deserves to be mentioned; this means that from a possible contact with fire, there will be no emission of toxic gases. The Alveolar Polycarbonate panel, while not enjoying the same transparency, offers greater lightness.

The limited weight of this panel guarantees a simple installation, letting the light pass and hiding any dirt, it is proposed as an optimal solution for the roofs of the Accident Prevention Protections, maintaining its qualities unchanged in the medium-long term. To unite the panels such as the Compact Polycarbonate and the Alveolar Polycarbonate, are the thermal insulation properties and even partial, those of acoustic insulation.

As for the Smoked Polycarbonate panel, it incorporates the quality of the other types of paneling, distinguishing itself for a transparency destined to remain unchanged over time. This will allow you to choose between the different shades of color it offers, starting from gray to brown.

This is why, in addition to covers, it is also used in the nautical sector, for example in windscreens and motorboat fairings.

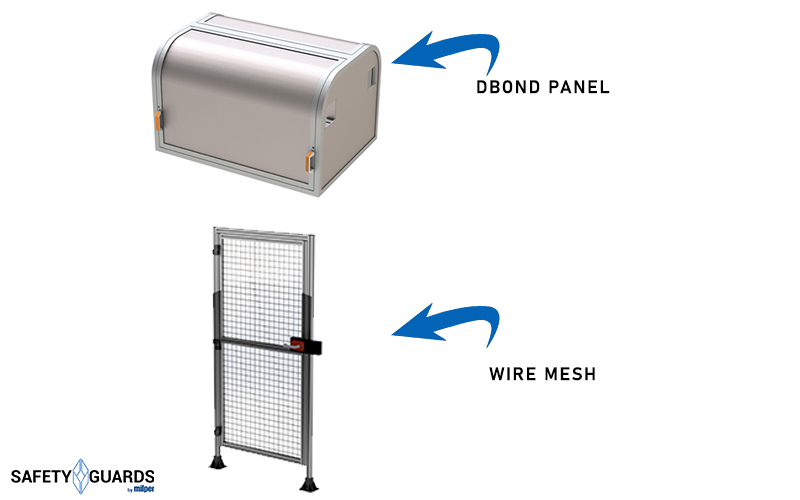

DBOND PANELING AND METAL NET

What characterizes the Dbond panel? the presence of two aluminum sheets, an extremely versatile material, hot bonded together on a layer of extruded polyethylene, placed in the center. The structure of this infill is a “sandwich”, which enriches the soundproofing properties of the panel.

Comparing this panel with the metal sheets, we note the absence of acoustic resonances, typical of metal. It is self-extinguishing and has no problem withstanding bad weather and chemicals.

The reduced use of noble alloy (consider the central part in synthetic material), makes the panel lighter and easier to handle. It can be subjected to different processing techniques, from cutting to shaping, it also offers high rigidity and maximum stability, making it an ideal support for printing. Instead it is called “Metallic Net” a grid formed by steel wires and transversal wires welded together by electro welding.

If you are looking for an infill that is resistant to bending, shear and stiffness and at the same time robust and economical, you will find it right in the Wire Mesh. This is the main reason for its diffusion in the construction of Protection Systems.

SUMMARY ON PANELS

The infill panels for industrial protections represent the solution to limit the heat exchange between internal and external environments. There are different types of paneling and each one sees the use of a specific material.

If the Compact Polycarbonate panels are preferred for their particular resistance to heat and water temperature and for the high degree of self-extinguishing, the Alveolar Polycarbonate is appreciated above all for its lightness.

For its part, Smoked Polycarbonate enjoys an excellent degree of transparency. To distinguish the Dbond from the other panels is the “sandwich” structure, which maximizes its soundproofing. Finally, the Wire Mesh is resistant to different types of processing (including cutting and bending), proving an ideal option for those looking for a very sturdy panel.