TRANSPARENT POLYCARBONATE

INDEX

1. POLYCARBONATE MATERIAL: WHAT TO KNOW

2. POLYCARBONATE FEATURES

3. TRANSPARENT POLYCARBONATE: TYPES

4. SUMMARY OF POLYCARBONATE

POLYCARBONATE MATERIAL: WHAT TO KNOW

Polycarbonate is a thermoplastic polymer that originates from carbon acid and that is used in various fields, often replacing glass. Although this polymer was born around 1928 thanks to the chemical company Dupont, its purely commercial use took place in the 1960s, thanks to General Eletric and Bayern, two multinationals.

Polycarbonates are particularly appreciated for their transparency, resistance, longevity and for all their thermal and electrical properties. It is not surprising that they are used a lot in the field of furniture but not only, there are many types that can be used in various sectors. This polymer is a polyester resin, but it is necessary to give several distinctions to understand its importance.

POLYCARBONATE FEATURES

Polycarbonate is able to resist oils, alcohols, petrol, acids and aliphatic hydrocarbons, as well as water below 70 °. This means that this material is able to withstand various bad weather, managing to maintain its characteristics over time. The only factor that could affect the integrity and induce a gradual decomposition, is the water above 70 °. Among its most appreciated properties are the mechanical ones, the material in fact manages to stretch, to support a heavy load and to resist any impacts, these qualities are fortified by increasing the molecular weight of the polycarbonates.

Their transparency allows the passage of light, the material absorbs UV rays, which causes a progressive yellowing. To avoid this phenomenon, stabilizers are used for all surfaces that will be exposed to atmospheric agents. The fact that many people tend to replace glass is thanks to this transparency, but it must be emphasized that it can be bent in conditions of excessive cold. Polycarbonate also has insulating properties, resistant to abrasion, steam and is more versatile than other plastic materials.

TRANSPARENT POLYCARBONATE: TYPES

The first polycarbonates put on the market were Bisphenols A: this material was very light and innovative, so it could be used in construction. After being used commercially, in more than 50 years, Bisphenol A is currently used to synthesize Polyester, polysulfonates, added to plastics for its antioxidant properties and also to PVC as it is a polymerization inhibitor.

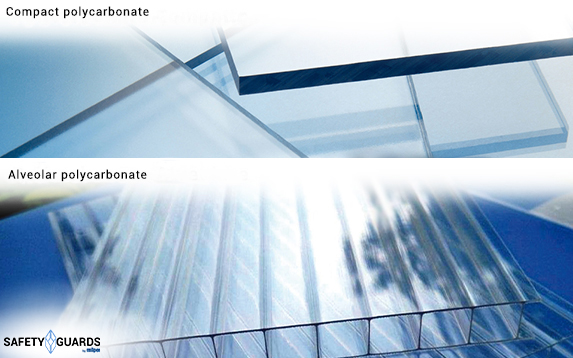

We find it in children’s products, bottles, sports equipment, medical aids, eyewear and many other products. Today it is possible to find two types of Polycarbonates: Compact Polycarbonate and Alveolar Polycarbonate:

- The Compact Polycarbonate is much more transparent than the second, and is very similar to glass, it is rigid and resistant so as to be unbreakable while being flexible. Finally, it is bright thanks to 89% of light transmission.

- Alveolar Polycarbonate has a characteristic cellular structure and is therefore used for roofing and building canopies; in fact it has a great resistance against atmospheric agents. The alveoli make it light and easily workable, which is why it is mostly used in the construction field.

In both cases, all the basic characteristics of the polycarbonates are respected, such as resistance, shockproof properties, excellent response to atmospheric agents and, last but not least, easy cleaning.

SUMMARY OF POLYCARBONATE

This universal material is used in many sectors, starting from the construction one up to the military one, and it is difficult to quantify the large amount of objects that surround you. Its diffusion is due to its multiple qualities, which intensify its versatility and make it more and more common.

In addition to its transparency, lightness and resistance, the use of polycarbonate is able to guarantee thermal insulation that keeps the temperature of the rooms constant and is not affected by the degrees outside. Finally, it must be considered that it is an easily workable material, especially cold, so that complex constructions and shapes can be obtained without stressing everything too much.