WORKPLACE SAFETY

INDEX

1. EN ISO 12100: RISK ASSESSMENT

2. EN ISO 13857: WHAT IT REGULATES AND ESTABLISHES

3. SAFETY DISTANCE CALCULATION

4. TECHNICAL STANDARD: IMPORTANCE OF SAFETY DISTANCE

5. THE SAFETY DISTANCE: FUNDAMENTAL PHASE

6. SUMMARY OF THE SAFETY DISTANCE

EN ISO 12100: RISK ASSESSMENT

The concept of Safety Distance is defined as a preventive measure to be adopted in order to reduce the risk, not only in the industrial but also in the civil sector. The Risk Assessment is therefore the necessary prerequisite, so that the Safety Distance can have its effective application. The reference technical standard for Risk Assessment is EN ISO 12100.

The risk assessment and intervention phase must comply with some fundamental steps:

- Analysis of real and potential risks.

- Elimination of risks at source.

- Implementation of accident prevention measures against operational risks.

- Staff reporting, training and information on risks that cannot be eliminated.

The Risk Assessment in the industrial field must take into account every possible aspect, in order to quantify the danger to which the operation is exposed. In this regard, the following points must be carefully considered:

- Identification of the human tasks associated with the life cycle of the industrial machine throughout its operational phase.

- Evaluation of the operational status of the machine at the time of the Risk Assessment.

- Identification of involuntary behavior by the operator and any reasonable foreseeable misuse.

- Evaluation of the limits of use of the operation of the machine: the standard contemplates any foreseeable reasonable incorrect use.

- Evaluation of the limits of use of the operation of the machine: the standard contemplates any domestic industrial use, the level of training required by the operator and the exposure of third parties to the danger.

- Space limitations in terms of:

- Range of motion.

- Space required for machine-operator interactions.

- Human interaction both as regards the machine-operator interface and the machine-energy source interface.

- Time limits in terms of routine maintenance.

- Limits in terms of characteristics of materials and operating environment.

- Identification of dangerous circumstances and events.

- Assessment of the dangerous area within which the person is exposed to the danger.

- Evaluation of the initial risks weighted by the operator towards the machine.

- Description of the protection measures integrated in the design of the production apparatus, as well as of all the protections adopted and of the complementary protection measures.

- Indications of the procedures and safety information in the workplace, in order to reduce the risk as per the instruction manual for use and maintenance.

- Final and residual Risk Assessment at the end of the Risk Assessment.

Although the focus is focused on the industrial context, the technical standard also takes into consideration the exposure of any personnel not involved in the operational maneuvers for the Risk Assessment. Therefore, the possibility of exposure to danger by the Employer, by employees with other tasks and even by the possible presence of children within the production area is also considered.

Overestimation and common sense constitute the pillars on which an effective Risk Assessment must be based. Each operating environment is made up of a specific organization of the individual areas according to the interaction of the operator with the machinery and the specific processing phases. Here, compliance with the aforementioned technical standard allows a Risk Assessment preparatory to the calculation of the Safety Distance.

EN ISO 13857: WHAT IT REGULATES AND ESTABLISHES

The Safety Distance is at the heart of the EN ISO 13857 technical standard. This constitutes the previously issued regulations regarding Safety Distance. Very detailed and clear, the directive regulates the measures to be taken into account when distancing areas exposed to danger. The legislation also includes the Safety Distance to be evaluated in the positioning of the Accident Prevention Guards. The text therefore constitutes a source of indications both for the design phase of the operating environments, and for the operational implementation of the Occupational Safety regulations in the industrial and work environment in general.

Classifiable under type B1, the aim of the directive of the international organization for standardization is to define the Safety Distance by means of specific values. The elements taken into consideration contemplate the limits within which the Industrial Protection structures are able to prevent both the reaching and the contact of man with sources of danger.

The calculation of the Safety Distance therefore derives from the evaluation of each parameter taken into consideration according to the EN ISO 12100 directive and applies the safety indications of EN ISO 13857. The level of punctuality is based on the concept of overestimation, since it applies the Risk Assessment meter in consideration of the possible access by a civil user in a non-industrial context. In fact, the text considers that the possibility that children of at least three years of age may come into contact with the area that is a source of danger.

SAFETY DISTANCE CALCULATION

The calculation of the safety distance therefore considers every aspect to be taken into consideration during the design phase. Both the dimensions and the shape of the Industrial Protections must be evaluated during the planning of the preparation of the production area. The Safety Distance must be applied in the technical decision of each opening of structures with the function of a Protection System.

The directive therefore constitutes a precise tool, capable of defining in detail every possible source of risk assessed and of providing a precise remedy. Among the aspects taken into consideration by the technical standard, there is the description of the components to be implemented, if the body enters the danger zone and in the case of contact between the source of danger and the limbs.

It is also considered the case of voluntary or accidental bypassing of the Accident Prevention Protection in order to implement the appropriate measures. Some aspects of the safety distance assessment can be summarized in the following points:

- The maximum size for the cracks – in order to prevent a person from entering the risk zone – is equal to: 180 mm vertically, 240 mm as a circular or square dimension.

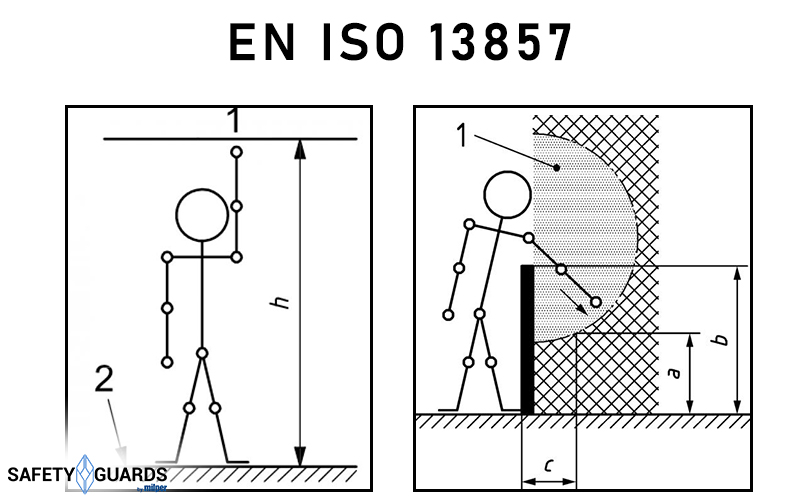

- The minimum height of the barrier protections can be less than 1000 mm. If there is a danger of overrun, it is necessary to implement strategies capable of strengthening the Safety Systems.

- Regarding the safety of the limbs, the standard takes into account the range of movements implemented according to the biometry of an individual of at least 14 years of age.

TECHNICAL STANDARD: IMPORTANCE OF THE SAFETY DISTANCE

The essential prerequisite for maintaining the safety distance is to be recreated only if the sources of danger and the industrial protection structures comply with the design criteria in terms of shape and position in space. The concept is fundamental since the Safety Distance is a parameter that derives from an exact calculation on the basis of the Risk Assessment. This is where the consequent design of the means of protection is based. It is therefore necessary to consider the following points, in order to guarantee the correct design function of the Industrial Protections.

- The reference plane must ensure that the operator remains in an upright position. Natural movements without forcing must be guaranteed, the same principle applies to the possibility of reaching out in the direction of the machinery, always respecting the Safety Distance.

- Prevent the use of chairs, ladders or raised parts: the reference plane cannot be altered in order to protect against the risk of voluntary or accidental climbing over.

- Do not allow the use of tools capable of indirectly allowing access of the upper limbs to the danger area.

Always in accordance with the directives of the EN ISO 13857 technical standard, the measurement of the Safety Distance must take place taking the most protruding part of the body as a reference. This is where the considerable weight of the evaluation of biometrics and biomechanics comes into play in the design of Protective Systems. In fact, the calculation of the Safety Distance starts from the evaluation of the dimensions and the ROM – Range Of Motion – applied to the movement of the operator’s joints.

THE SAFETY DISTANCE: FUNDAMENTAL PHASE

The Risk Assessment phase is fundamental, depending on the Safety Distance to be adopted. It therefore appears reasonable and consequential that this distance increases in a way that is directly proportional to the assessed risk and with an inverse proportionality to the level of Accident Prevention Protections in the design phase.

In this regard, the technical standard EN ISO 13849-1 places the accent precisely on the choice of the right proportion to be adopted in the logic of definition of the Safety Distance. In fact, this directive indicates the parameters to be referred to in relation to the assessed risk and the related implementation reduction. Risk reduction is evaluated through a defined control system in order to determine the level of solutions to be implemented.

The underlying principle is based on an excess evaluation, so as to protect the safety at work to the highest degree. Therefore, if a “level A” emerges from the Risk Assessment, the technical standard indicates the application of a “level B or C” Protection System. To an increasing level of danger it is therefore necessary to apply a pejorative parameter which corresponds to a higher level of the measures adopted.

The aim is to maximize protection for operators, staff and any visitors to the production unit. It is necessary that the design study of the Safety Distance involves the main company figures starting from the CDA to the Technical Office, to the head of the production department, up to the contact person for Safety at Work. Legislation is a valuable tool for careful and far-sighted planning.

SUMMARY OF SAFETY DISTANCE

The definition of Safety Distance includes the industrial and civil sectors. Risk Assessment is the prerequisite for implementing an effective strategy. Risk Analysis, their elimination at source and prevention and information measures are essential steps. Risk Assessment – according to EN ISO 12100 – involves an analysis of the technical – machine – and human – aspects in the assessment of possible behaviors -.

A great deal of weight is attributed to the degree of expertise required by the operator and to the study of useful operating spaces. It is important to evaluate the state of the systems and the maintenance time limits. The assessment considers the prevention measures already adopted as well as the safety devices of the machinery. The evaluation of the Safety Distance must be based on a first phase of careful analysis that takes into consideration the possible presence of non-assigned personnel.

The EN ISO 13857 technical standard defines the Safety Distance to be adopted. The directive regulates the measures to be taken in spacing out areas exposed to danger. Industrial Protections must therefore respect precise references as regards the Safety Distance. Being a level B1 directive, the technical standard is characterized by a careful estimate of the limits to be observed in order to prevent contact between man and the source of danger.

The overestimation of the risk is the basis of the technical standard, the yardstick is in fact the possibility of access to danger calculated in a civil context. The text considers the possible contact of danger by children aged three and over. The calculation of the Safety Distance, therefore, takes into consideration the parameters useful in the technical field for the design of accident prevention means.

In fact, the Safety Distance is taken into account for the Risk Assessment of the dimensions of the openings, as well as the behavior to be adopted if the person is inside the danger area. Exact measurements apply to the design of the cracks, the evaluation of the heights and the dimensioning of the areas intended for operational movement by the operator. The Safety Distance therefore assumes a useful role only in function of compliance with the design criteria of the Industrial Protection means.

Based on the exact data of the Risk Assessment, the operation of the Safety Distance presupposes compliance with the design parameters. The reference plane must therefore remain such as to guarantee natural movement for the operation. It is not possible to use elevators or the use of tools that go beyond the danger zone.

The technical standard EN ISO 13849-1 indicates an excess evaluation of the risk level, in order to optimize the safety measures within the limits of reasonable caution. It is good that every player in the company is involved in the process of assessing and preparing the occupational safety plan.