ALTERNATIVE OPENINGS

INDEX

1. INDUSTRIAL PROTECTIONS: TYPES OF DOORS

2. SWING DOOR: TECHNICAL ASPECTS

3. SLIDING DOORS: THEIR REALIZATION

4. ACCIDENT PREVENTION PROTECTIONS: ALTERNATIVE OPENINGS

5. SUMMARY ON INDUSTRIAL PROTECTIONS AND THEIR OPENINGS

PROTECTION SYSTEMS: TYPES OF DOORS

When security, speed and process integration are the challenge, the study for the application of intelligent doors to industrial protections for machines is essential. High speeds in short cycle times require extra care and attention.

Automated production and assembly require very advanced technology, processes and equipment. This is why it is advisable to choose high-speed, high-performance doors, particularly suitable for even very demanding conditions.

The doors of the Industrial Guards for machinery, are the best safety barrier in the sector. In fact, there is no type of device that can match its security levels. The door can be integrated directly into the control systems of the automated machine.

When this integration is complete, the door’s security features meet a number of standard requirements critical to industry experts. The doors of the industrial protections for machinery are equipped with very specific characteristics, since they must provide valid support for operations carried out on a large scale, they do not hinder human work, but protect it at 360 degrees.

As an alternative to or integrated into the doors, regardless of their type, with or without Safety Switches, we can consider the use of photocells which can be integrated into the frames of the machinery. Among the models on the market there is a variety of different options, with swing, sliding or folding door models, and each one has its own specific set of features and functions, making them an ideal solution for particular scenarios.

In summary, we can say that the solutions may appear to be standard, but in reality they adapt to the particular situation. The professionalism of the experts in the sector serves precisely to guarantee total correspondence between the product and the customer’s needs.

The doors of the Industrial Guards for machinery help to save time, space and construction costs, improving safety and increasing production yields. With rapid opening and closing speeds, the doors of the Industrial Protections are specifically designed for example for the following purposes:

- Protect operators who use industrial machines from blunt objects that could be projected from the inside to the outside of the machines themselves, especially in the presence of particularly heavy materials with high chip removal processing speeds.

- Increase usable factory floor space with automated guard systems, which require a smaller work cell footprint and safety doors with a true physical barrier, allowing the employee to work safely while closer to the machine.

- Industrial machine protection systems increase production and reduce costs by allowing one employee to safely operate multiple industrial machines simultaneously.

- The main technical characteristics of the industrial protection door of a machine include variable frequency drives (VFB) for high cycle operations, safety switches and reversing photocells, and various communication interfaces, such as I / O card, Ethernet / IP and PROFINET.

It is important to be supported by companies specialized in the construction of Safety Guards, with many advantages:

- Save time in the design and construction of your own machinery.

- Be updated on all the most suitable materials available on the market for the construction of doors for safety protection.

- Use the accessories built into the doors with features dedicated to use, such as Adjustable Hinges.

- In the specific case of doors, it is essential to adopt the most correct and suitable closing devices.

SWING DOOR: TECHNICAL ASPECTS

The swing doors of the Industrial Protections are designed to limit access to dangerous movements of robots or other types of machines, while the process appears, while offering greater protection for the operator who is using the machine itself, or a piece of machinery proximity.

The doors of the Accident Prevention Guards for industrial machinery therefore protect personnel from dangers associated with the production processes. Combined with Safety Devices, these Safety Guard doors, whether more or less automated, offer ideal protection, limiting access and protecting against dangers caused by the work process.

Among the types of doors to be included in Industrial Protection, the swing door model is undoubtedly the most classic, and in some respects the most used. Characterized by the presence of two hinges and one or more handles, placed in the perimeter opposite to that of the hinges, it is the ideal solution in terms of cost, efficiency and durability.

When choosing between the types of functional doors to protect machinery, size plays a fundamental requirement. In fact, in the absence of space, the optimal solution becomes, in any case, the insertion of sliding doors, which we will discuss in the next paragraph.

We can associate the use of springs to the functioning of swing doors, the simplest being the mechanical ones, suitable for light workloads. Made with a simple helical winding system, the mechanical spring represents an option for this type of door, as opposed to the gas spring, which must be used only when necessary.

The Mechanical Springs can be applied inside the rotational movement of the Hinges, reducing their weight and therefore the force exerted by the operator of industrial machines during the continuous opening and closing activity. In most cases where the door has a considerable size, it is willing to opt for the use of a spring system for opening.

This type of Gas Spring is particularly useful when the doors open upwards, making the thrust system support both the weight of the door and its opening. Consisting of a steel cylinder with pressurized nitrogen inside, it has a rod which, via a sealing ring, enters the cylinder when the door is opened or closed. Thanks to the presence of an oil, the lubricating and braking actions are guaranteed.

If you want the opening to have a free stroke, you can opt for a gas spring with a hole-to-hole connection. This does not have to involve the use of threaded pins, it can be applied by limited rotations and with perfect alignment.

If for working practicality the most comfortable system instead provides for a door that can be locked at different levels during opening, the most correct Gas Spring attachment is the articulated one. In fact, the latter allows wider and non-aligned rotations.

On the other hand, it will not be possible to use these systems when the machinery has high levels of vibrations, when the temperature exceeds 80 degrees centigrade, instead of shock absorbers, in particularly corrosive environments.

SLIDING DOORS: THEIR REALIZATION

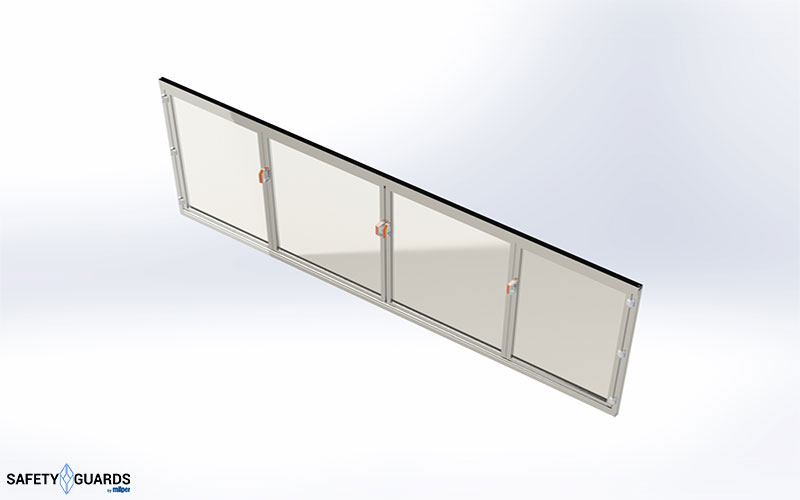

Sliding doors are the best option for situations where there is not enough space for a swing door. Just like swing doors, sliding doors can be opened and closed with pull handles. The materials are specially selected to ensure that they provide the appropriate level of security and easy sliding of the doors, so that the mechanism is smooth, fast and above all safe.

However, one specific type or style does not fit all and it is crucial to choose the correct door for the needs of the business and facilities being used. That’s why a customized quote is always necessary, drawn up by technicians who have many years of experience in the sector.

Sliding doors are typically fastened to a rail at the top, and fitted with a rail at the bottom. This ensures that the door always opens and closes smoothly. The configuration can be totally personal, in fact it is possible to choose a pneumatic or electric door, just as it is possible to decide whether the openings should take place to the right or to the left.

The sliding door can be built with mesh, polycarbonate or steel panels, to adapt to the accident prevention system chosen for the machine. Even in sliding doors, gas springs can be used or the use of counterweights installed with chains.

These are in fact the best choices in the movement of vertical doors, since they allow the weight of the doors to be reduced or eliminated, allowing you to follow the opening and closing actions effortlessly and quickly, saving time and money.

These models can also be fitted with a proximity switch, connected to the Safety Switch Multi-bracket, mounted on the side of the door leaf. The gas springs and counterweights are suitably calculated based on the exact weight of the door. Depending on the Risk Assessment, it is necessary to choose the most suitable Safety Device to connect, and integrate with all the other devices of the industrial machines.

ACCIDENT PREVENTION PROTECTIONS: ALTERNATIVE OPENINGS

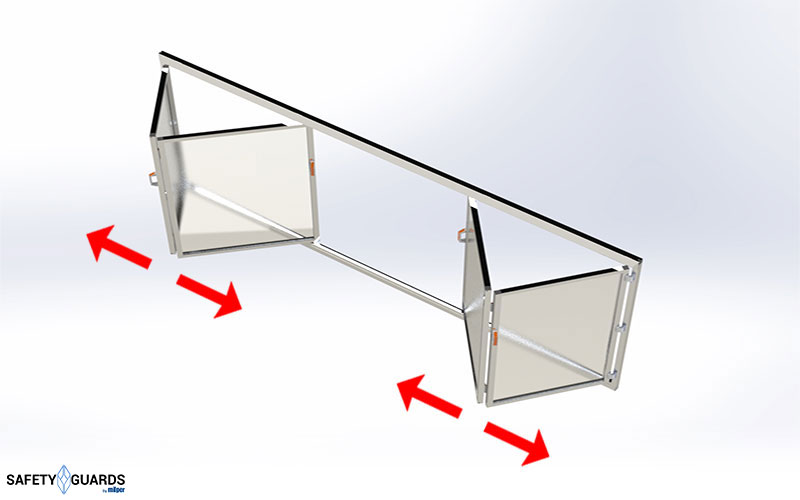

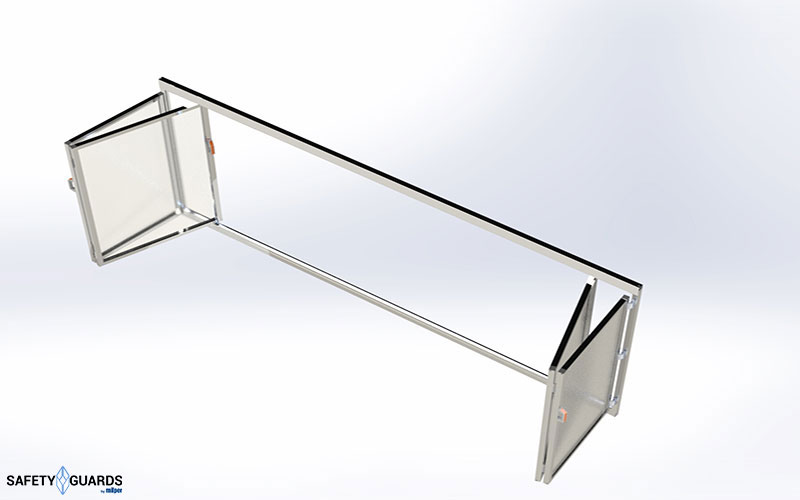

An alternative opening to that of the hinged and sliding door is the folding opening, also called folding door, this is a very flexible door that takes up little space in the open position, but still creates a large opening space with free access in height.

To be preferred in situations where the size of the door requires a compromise to the swing opening but it is preferable not to let the track of the sliding type take up space. When it comes to openings, we cannot forget to consider pneumatic accessories, such as handles and safety switches.

While the former must relate to the mail both from a functional point of view and from an aesthetic point of view, the latter are very important as a security measure. In fact, it is possible to add a Safety Switch to the Industrial Protection of the machine, i.e. a mechanism installed on the door of the Accident Prevention Protection of the industrial machine.

This will give a signal to the machine if the door is opened and simultaneously stop it, so it is not moving while employees are inside the production area. The Technical Standard EN ISO 14119 regulates the Interlocking Devices, which provides all the standards that must be respected when creating Safety Devices, as well as the requisites necessary to identify the correct installation, furthermore, the technical standard governs production and installation .

In fact, the four types with which devices are cataloged are mentioned here: type 1, activated by a non-coded hinge, rotary cam or linear cam actuator; type 2 mechanically operated with coded actuator, such as key with separate or trapped actuator; type 3 operated without contact, with non-coded actuator, its operation is inductive, i.e. magnetic, capacitive or ultrasonic; type 4 also operated without contact, with coded actuator, its operation is with coded magnet.

SUMMARY OF INDUSTRIAL PROTECTIONS AND THEIR OPENINGS

Whichever model of door you choose, you must always remember that in accident prevention systems, the principle of necessity is the master. The elements to be analyzed are:

- The thrust force, calculated in relation to the position of the attachments and the weight of the door.

- The travel, which must be able to allow the maximum travel both when opening and closing the door.

- The height of the Handle, which must be positioned in an ergonomic way for the user, guaranteeing easy and comfortable accessibility.

Therefore, in order to choose the most suitable door for your situation, you need to carefully evaluate the space and environment in which the Security and Protection system will be installed. Opening through the swing door requires a large amount of space since, in addition to the size of the machinery, the space occupied by the open door must be taken into account.

In fact, this must not obstruct either the passage in the surrounding area, or the fluidity of the movements of the operator of large doors. Thanks to the gas spring technology, sliding doors are also an excellent solution, especially when the doors are large and heavy.

With these devices, opening and closing are facilitated and the operator will have much less effort than with swing openings, characterized by the presence of a mechanical spring. In the case of vertical sliding doors, in addition to the gas springs, also the devices with chain-supported counterweights are an excellent solution for reducing the overall dimensions when opening and closing the doors.

In all four of these types of door, the choice of the Safety Interlock is also important. Depending on the type of machinery or ideal Industrial Protection, this Safety Device, regardless of which of the four types it belongs to, acts as an extreme guarantor against any accident.

Handles are also details that should not be underestimated when choosing doors for Protection Systems. These must be aesthetically pleasing, perhaps the type of captivating design, but must at the same time be functional and make the operator’s work easier and lighter.